In nature, copper is present as a constituent in various minerals. In its pure refined state, copper is a pinkish malleable metal that belongs to the same group of elements in the periodic table as silver and gold. Copper metal spontaneously oxidises forming a surface oxide. In contact with air and humidity, both indoors and outdoors, this oxide evolves forming a patina of varying chemical composition. This patina shows different visual appearance that reflects the environmental conditions. Copper metal exposed in low pollution atmospheric environments generally reveals a brown/black appearance and the presence of more polluted conditions including sulphates and/or chlorides result in a green/blue-green appearance [Atmospheric Corrosion, 2016]. These visually different appearances and beneficial mechanical and corrosion properties have made copper an appreciated construction material both at outdoor and indoor conditions including, e.g. touch surfaces.

Copper is the base metal in many alloys such as brass (Cu-Zn), bronze (Cu-Sn) and copper-nickel, materials which possess different intrinsic properties compared with the pure metals.

Copper is an essential metal for humans, animals and plants and is, in the right concentrations and chemical form, vital for their survival. Copper is also a well-documented antimicrobial agent, a character that already was recognised by the ancient Egyptians whom for example used it to sterilise wounds and drinking water. Various modern-day studies have shown copper to quickly (within hours) and efficiently (>95 %) kill a wide variety of bacteria, both gram-positive and gram-negative. Copper surfaces have shown to keep their antimicrobial properties even after repeated bacterial deposition.

Copper and several copper-based alloys are approved by the US Environmental Protection Agency (USEPA) as antimicrobial materials. Copper alloys have though been shown to be less efficient than the pure copper metal.

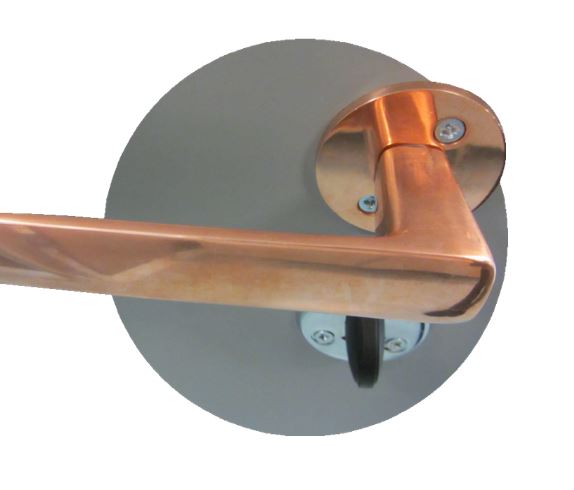

The use of copper-based alloys as touch surfaces in furnishings and fittings in hospitals has been shown to efficiently reduce the presence of microorganisms.

It has further been shown that the composition of the antimicrobial material surface has an impact on its antibacterial behaviour. For example, the copper(I)oxide compound, Cu2O, has been shown to have better antimicrobial properties compared with the copper(II)oxide compound, CuO [Hans et al. 2013]. If other organic materials apart from bacteria are present on the surface, they will interact with the copper surface and reduce the antimicrobial properties. Thus it is important to monitor the indoor corrosion process and characterise the surfaces to obtain the best possible antimicrobial results but also to clean the surfaces regularly to maintain the antimicrobial properties.

The use of copper inhibits the development of antimicrobial-resistant organisms and reduces the risk of MRSA and other antibiotic-resistant bacteria in, e.g. hospital environments.

There are a few suggested mechanisms for the killing of bacteria on copper surfaces. Direct contact with massive copper is believed to rupture the cell membrane of the bacteria by disturbing the transmembrane potential that controls the outer membrane of the cell. After the creation of pathways through the cell membrane, copper ions can easily enter the cell and generate reactive oxygen species (ROS), which induces oxidative damage and finally DNA degradation.

Copper Development Association. Copper Brass Bronze Design Handbook, Architectural Applications. 2019-02-04. https://www.copper.org/publications/pub_list/pdf/A4039-ArchitecturalApplications.pdf

Delgado, K. et al. Polypropylene with embedded copper metal or copper oxide nanoparticles as a novel plastic antimicrobial agent. Letters in Applied Microbiology 2011, 53, 50–54. https://doi.org/10.1111/j.1472-765X.2011.03069.x

Grass, G., Rensing, C. and Solioz, M. Metallic Copper as an Antimicrobial Surface. Applied and environmental microbiology 2011, 1541–1547. https://doi.org/10.1128/AEM.02766-10

Hans, M. et al. Role of copper oxides in contact killing of bacteria. Langmuir, 29, 2013, 16160−16166. https://doi.org/10.1021/la404091z

Karpanen, T. et al. The Antimicrobial Efficacy of Copper Alloy Furnishing in the Clinical Environment: A Crossover Study. Infection Control & Hospital Epidemiology 2012, 33(1), 3-9. https://doi.org/10.1086/663644

Leygraf, C. et al. Atmospheric Corrosion, 2nd edition. John Wiley & Sons 2016. https://www.wiley.com/en-se/Atmospheric+Corrosion,+2nd+Edition-p-9781118762271

Michels, H. T. and Anderson, D. G. Antimicrobial regulatory efficacy testing of solid copper alloy surfaces in the USA, Metal Ions in Biology and Medicine: Vol. 10. Eds Ph. Collery, I. Maymard, T. Theophanides, L. Khassanova, T. Collery. John Libbey Eurotext, Paris, 2008, 185-190. https://www.antimicrobialcopper.org/sites/default/files/upload/media-library/files/pdfs/uk/scientific_literature/mibm-epa-reg-copper-michels-2008.pdf

Noyce, J. O., Michels, H. and Keevil C.W. Potential use of copper surfaces to reduce survival of epidemic meticillin-resistant Staphylococcus aureus in the healthcare environment. Journal of Hospital Infection 2006, 63, 289e297. https://doi.org/10.1016/j.jhin.2005.12.008

Warnes, S. L. and Keevil, C. W., Mechanism of copper surface toxicity in Vancomycin-resistant Enterococci following wet and dry surface contact, Applied and environmental microbiology, 2011, 6049-6059. https://doi.org/10.1128/AEM.00597-11